|

|

| |

Current position --Production technology |

|

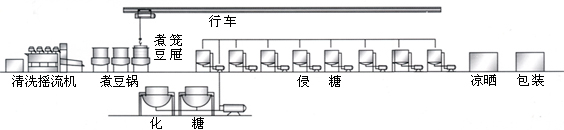

| Technology flow image of production line of red bean soaked in sugar liquid |

|

清洗摇流机 |

煮豆笼屉 |

煮豆锅 |

行车 |

化糖 |

浸糖 |

凉晒 |

包装 |

washing shaking flow machine |

bean boiling bamboo steamer |

bean boiling pot |

travelling crane |

melt sugar |

soaking in sugar liquid |

cooling and dry |

package |

|

The production line makes finely chosen red bean into excellent bean production after such steps as washing, boiling, soaked in sugar liquid, dry and package and so on. The production line has won the popularity of factories of frozen food and stuffing products.

main technical parameter: |

production ability |

total power |

exhausted water |

exhausted steam |

workshop area |

3t/8h |

15KW |

3t/h |

800kg/h |

150m2 |

|

|

| |

|

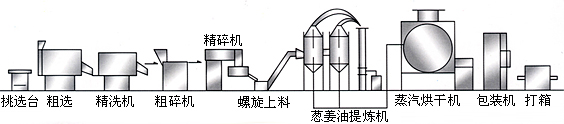

| Technology flow image of production line refining garlic and ginger oil (powder) |

|

挑选台 |

粗选机 |

精洗机 |

粗碎机 |

精碎机 |

selecting platform |

rough choice |

finely washing machine |

roughly washing machine |

finely washing machine |

螺旋上料机 |

葱姜油提炼机 |

蒸汽烘干机 |

包装机 |

打箱机 |

spiral material loading |

extracting machine of scallion and ginger oil |

steam dryer |

packing machine |

baling |

|

Adopting the advanced technology, during the process of making garlic and ginger powder, the production line extract garlic oil and ginger oil to create bigger economic profit.

main technical parameter: |

production ability |

total power |

exhausted water |

exhausted steam |

workshop area |

1.5t/8h |

45KW |

5t/h |

600kg/h |

400m2 |

|

|

| |

|

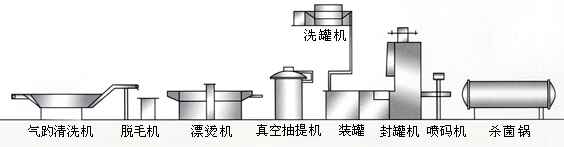

| Technology flow image of strawberry tomato deep processing |

|

气趵清洗机 |

脱毛机 |

漂烫机 |

真空抽提机 |

洗罐机 |

装罐 |

封罐机 |

喷码机 |

杀菌锅 |

air washing machine |

hair removing machine |

washing & scalding machine |

vacuum extracting machine |

pot washing machine |

pot loading |

pot sealing |

code spraying machine |

sterilization pot |

|

The production line is applied to make selected strawberry and tomato into all kinds of canned products after such steps as hair and thorn removing, continuous scald and washing, cooling, vacuum extract, color fixing, canned, sealing and sterilization and so like.

main technical parameter: |

production ability |

total power |

exhausted water |

exhausted steam |

workshop area |

5t/8h |

30KW |

10t/h |

1000kg/h |

400m2 |

|

|

| |

|

|

|